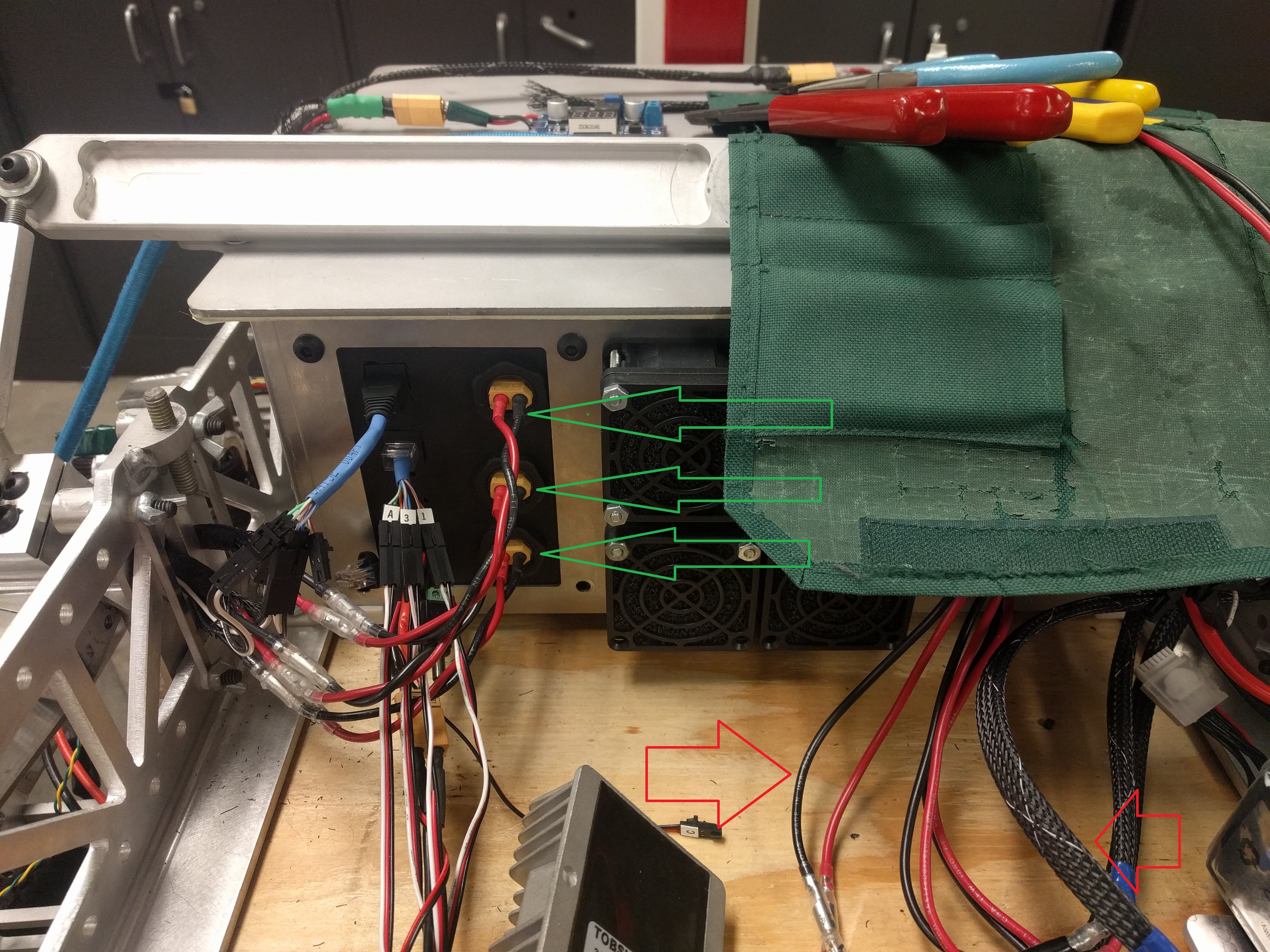

Last week, I was working on cleaning up some wiring, specifically the wiring providing power to the wheel motors controllers. When it was originally done, we weren’t sure if the length would be changing, so we left them long (about an extra foot on each cable). This meant that they were hanging down under the rover and were generally in the way. We now know that we are not changing the suspension before competition, so I decided to fix the length. It looks much nicer now.

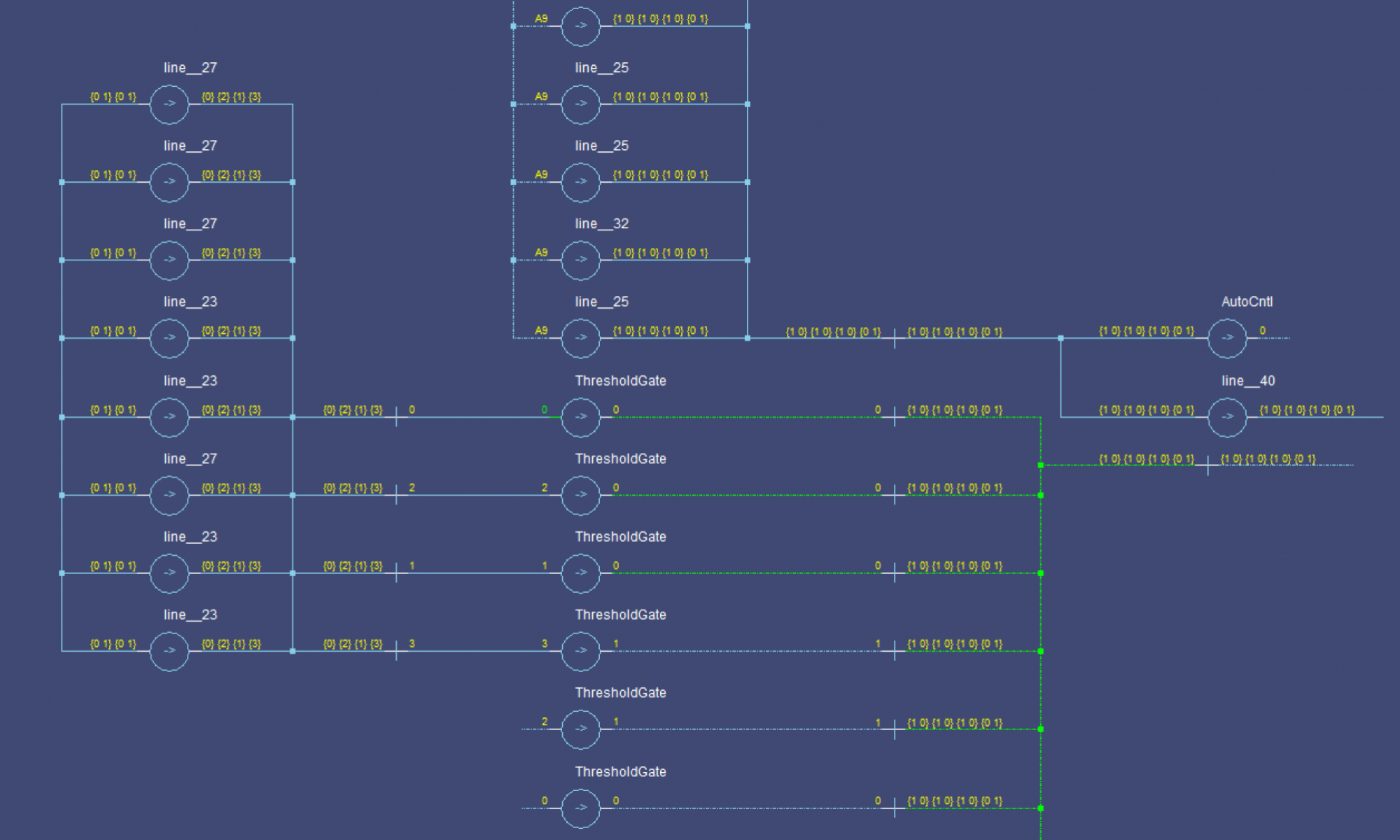

Jump to Saturday, we go to start a test drive, power on the rover and hear some clicking/popping sounds. We check all the LEDs and one of the motor controllers is not working. A review of the wiring on the left side of the rover (right in above image) showed that I had plugged a pair of wires in backwards. Now, I’m usually a careful guy, and I did actually attempt to check the wires, I just did so incorrectly (clearly).

Further diagnostics on the motor controller showed that the internal microcontroller was fine, but all the power transistors for the H-bridge were fried. Thankfully, we had spares ordered already.

Events like this are why I usually opt for polarized, grouped connectors for my cables (XT60s are amazing) but sometimes there are external constraints in place. We have a very tight window for those cables to fit through, and it is not possible to push a solid multiple-pin power connector through the window. We are using bullet terminals because they are very close to the size of the wire, and allow the wires to be pushed through individually.

This has reinforced my opinion on polarized connectors as a necessity, and served as an excellent reminder to always check your new/modified thoroughly connections before activating a system. It is especially important to identify things that you are doing in a riskier manner, and check them extra carefully. Know your risks, and watch them closely.